How Gearbox Manufacturers Are Adapting to Consumer Demands

You might be surprised to learn how gearbox manufacturers are evolving to meet your changing expectations. As you demand more efficiency, durability, and sustainability, these manufacturers are stepping up their game by integrating smart technologies and innovative materials into their designs. They’re not just chasing trends; they’re aligning their products with your values and preferences. But what does this mean for the future of gearboxes, and how will these adaptations impact the industry as a whole? The answers might challenge your perceptions.

Shifting Consumer Expectations

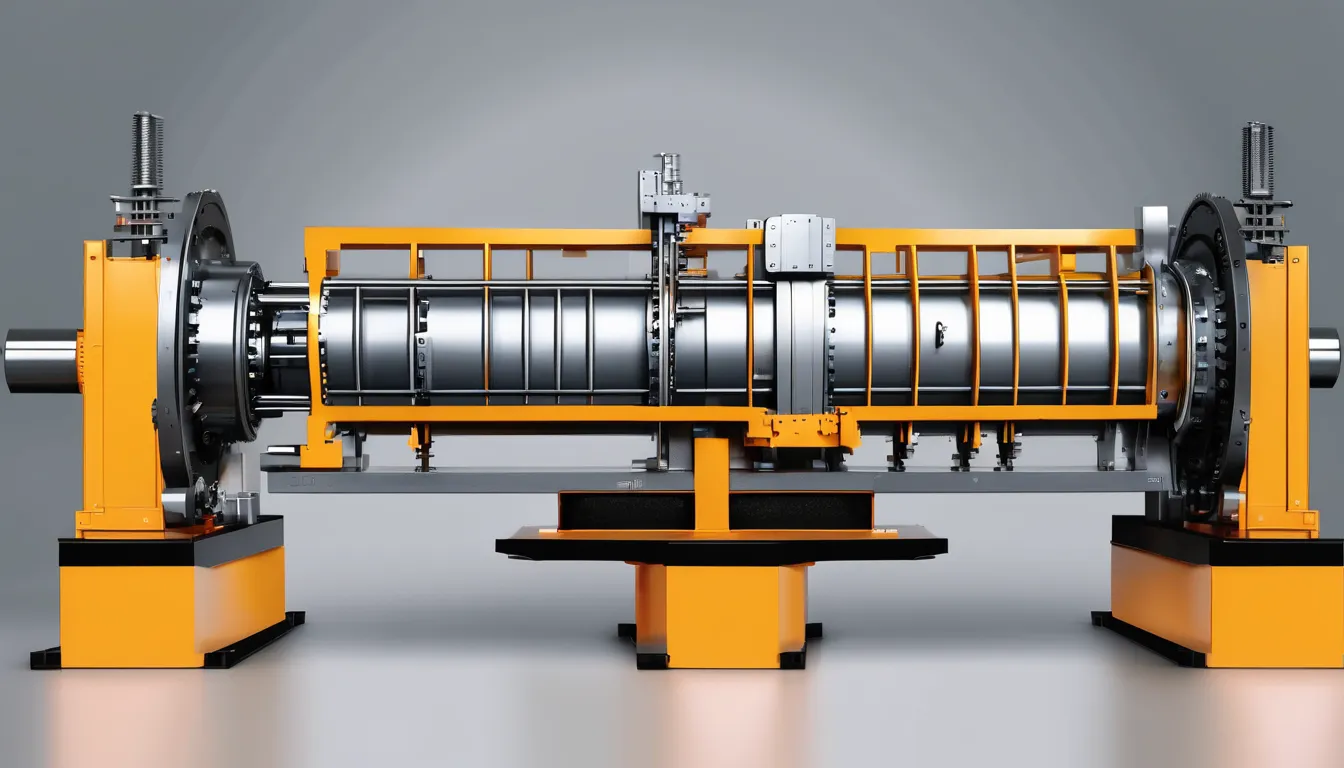

In today’s fast-paced market, consumers expect more than just basic functionality from their gearboxes; they want efficiency, durability, and innovation.

As a consumer, you’re likely seeking products that not only perform well but also offer long-lasting value. This shift in expectations means that gearbox manufacturers must step up their game to meet your demands.

You want gearboxes that can withstand harsh conditions while delivering optimal performance. Manufacturers are responding by investing in advanced materials and cutting-edge technologies, ensuring their products can handle increased loads and reduce wear.

You’re also looking for energy-efficient designs that minimize power loss, which translates into lower operating costs for you.

Innovation is key; you want features like smart technology integration that allows for real-time monitoring and adjustments.

This need for customization is prompting manufacturers to develop gearboxes tailored to specific applications, giving you more options to choose from.

Ultimately, your expectations are driving a transformation in the industry, pushing manufacturers to prioritize not just functionality but also performance, sustainability, and adaptability.

Your voice matters, and manufacturers are listening closely to what you demand from your gearboxes.

Embracing Sustainable Practices

Manufacturers are increasingly recognizing the importance of sustainability in response to your evolving expectations. You want products that not only perform well but also have minimal environmental impact. To meet these demands, gearbox manufacturers are adopting sustainable practices throughout their operations.

One significant change is the shift toward energy-efficient production methods. By reducing energy consumption during manufacturing, they’re not only cutting costs but also lowering their carbon footprint. You’ll find that many manufacturers are investing in renewable energy sources, making their facilities greener.

Additionally, companies are focusing on waste reduction. They’re implementing recycling programs and optimizing material usage to minimize waste. This commitment to sustainability resonates with you as a consumer who values eco-friendly practices.

Manufacturers are also considering the entire lifecycle of their gearboxes. They’re designing products for longevity and ease of repair, which means you won’t have to replace them as often. This approach aligns with your desire for durable, sustainable products.

Innovations in Material Usage

Shifting gears in material usage, gearbox manufacturers are exploring innovative alternatives that enhance both performance and sustainability. You’ll notice that many companies are now turning to lightweight composites and advanced alloys, which provide increased strength without the added weight.

This shift not only improves energy efficiency but also extends the lifespan of gearboxes, reducing the need for replacements.

Additionally, manufacturers are investing in biodegradable materials and recycled components. By incorporating these eco-friendly options, they’re minimizing their environmental footprint while still delivering robust products.

You may find that some brands are even experimenting with 3D printing technologies, allowing for more precise designs and less waste during production.

Another exciting development is the use of nanotechnology to improve the wear resistance of materials. This innovation can lead to smoother operations and reduced friction, which translates to better performance in demanding applications.

As a consumer, you can expect gearboxes that not only meet your performance needs but also align with your sustainability values.

Integration of Smart Technologies

Gearbox manufacturers are embracing smart technologies to enhance performance and user experience. By integrating these advanced solutions, they’re not just keeping up with consumer demands; they’re setting new standards in efficiency and reliability.

Here are some key benefits you can expect from smart technologies in gearboxes:

- Real-Time Monitoring: You can track the performance of your china Custom gear solutions in real-time, allowing for immediate adjustments and reducing downtime.

- Predictive Maintenance: Smart sensors alert you to potential issues before they become major problems, helping you avoid costly repairs and extend the lifespan of your equipment.

- Enhanced Efficiency: Automated systems optimize gear performance, resulting in lower energy consumption and reduced operational costs.

- Data Analytics: By utilizing data collected from your gearbox, manufacturers can provide insights that help you make informed decisions about usage and maintenance.

With these advancements, you’re not just getting a gearbox; you’re gaining a smart system that adapts to your needs.

As manufacturers continue to innovate, you’ll find that integrating smart technologies will profoundly impact your operations, making them more efficient and reliable.

Customization and Flexibility in Design

How can customization elevate your gearbox experience? When you tailor a gearbox to your specific needs, you gain efficiency and performance that off-the-shelf models often lack. Gearbox manufacturers are increasingly offering customizable options, allowing you to choose the materials, design features, and configurations that best suit your application.

Whether you’re in automotive, aerospace, or industrial sectors, having the flexibility to modify gear ratios or housing designs means you can optimize functionality for your unique demands.

You’ll notice improved reliability and life expectancy when you adapt a gearbox to your operational requirements. Customization isn’t just about aesthetics; it’s about achieving the right balance between performance and durability.

Manufacturers are embracing modular designs that make it easier to incorporate various components, enabling quicker adjustments and upgrades as technology evolves.

Additionally, this level of flexibility fosters innovation. As you collaborate with manufacturers on your design, you’re not just selecting parts; you’re engaging in a process that can lead to breakthrough solutions tailored specifically for your operation.

Ultimately, customized gearboxes can propel your projects forward, ensuring you remain competitive in a rapidly changing market.

Conclusion

As you can see, gearbox manufacturers are actively responding to your demands by focusing on efficiency, sustainability, and innovation. They’re not just improving performance but also aligning their practices with your values. With advancements in material usage, smart technology integration, and customizable designs, you can expect gearboxes that meet your specific needs while minimizing environmental impact. This commitment to adapting ensures you receive reliable, cutting-edge solutions that enhance your operations and support a sustainable future.